At Pro Cut Water Jet cutting we offer quality water jet cutting as part of our turnkey solutions or for one-off projects. We are the only commercial water jet cutting service in central Victoria, ensuring you don’t have to travel far for world class services. Water jet cutting offers excellent accuracy, quick set-up time and fast cutting, while also handling a wide range of materials with no Heat Affected Zone (HAZ) or change in material properties.

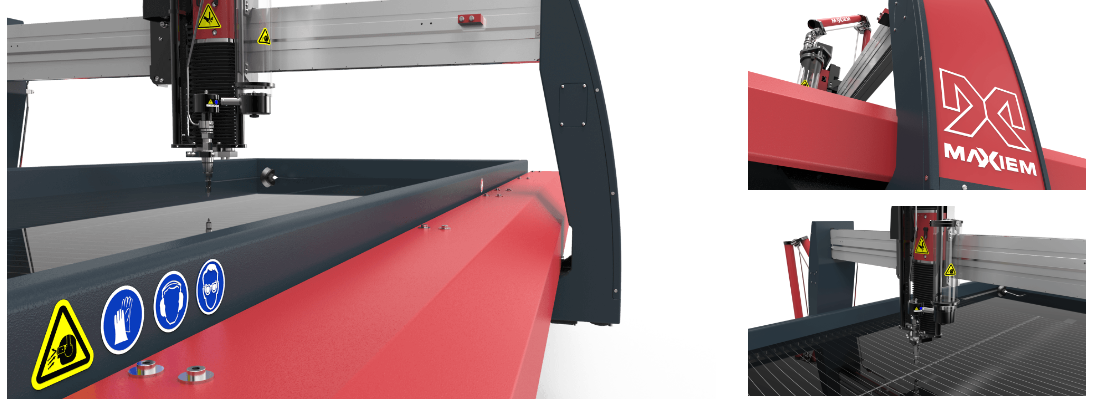

Our MAXIEM 1530 is designed for a wide range of machining needs and sets a higher standard for precision abrasive water jet machining. The rigid tank design is scaled to handle common plate sizes with room to spare. The advanced linear motion system uses digital linear encoders to provide instant micron-level cutting head position feedback to the controller to assure accurate part production. Equipped with a diamond integrated MAXJET 5i Nozzle, the 1530 can cut virtually any material quickly and efficiently.

Perforated sheeting

Custom plates and cleats

Pre cut sheet metal and plates for further folding and bending

Custom exhaust plates.

Engine brackets.

Infill panels.

Custom mounting brackets

Fire pits

Garden Beds

Planter boxes

Decorative screens

Fencing extension panels

Cutting of steel plates up to 100mm thick.

Cutting of high tensile plates.

High tensile Wear plates

Hopper panels and patches

Water jet cutting compares favourably with other cutting methods, offering good accuracy, fast set-up time and fast cutting, while also cutting a wide range of materials with no Heat Affected Zone (HAZ) or change in material properties.

Water jet cutting leaves behind a satin-smooth edge, reducing secondary operations

Fastest cutting speeds and best precision compared to any competitive abrasive water jet in the industry.

Machines a wide range of materials and thicknesses, from metals and composites to glass and plastics.

Environmentally “green” system with quiet and clean operation with low electrical consumption. The water jet cutter emits no noxious gases, liquid or oils used in, or caused by, the machining process.

Backed by Omax exclusive Intelli-MAX Software with real world cutting data.

Footprint* (L x W) : 4,293 mm x 3,302 mm

Height** : 3,200 mm

Weight (tank empty) : 1,814kg

X-Y Cutting Envelope *** : 3,048 mm x 1,575 mm

Z-Axis Travel *** : 305 mm

Table Size – (L x W) : 3,708 mm x 1,727 mm

Speed: 12,700 mm/min

Linear Positional Accuracy : ±0.0762 mm

Repeatability : ±0.0254 mm

Ballbar Circularity : ±0.1270 mm